- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

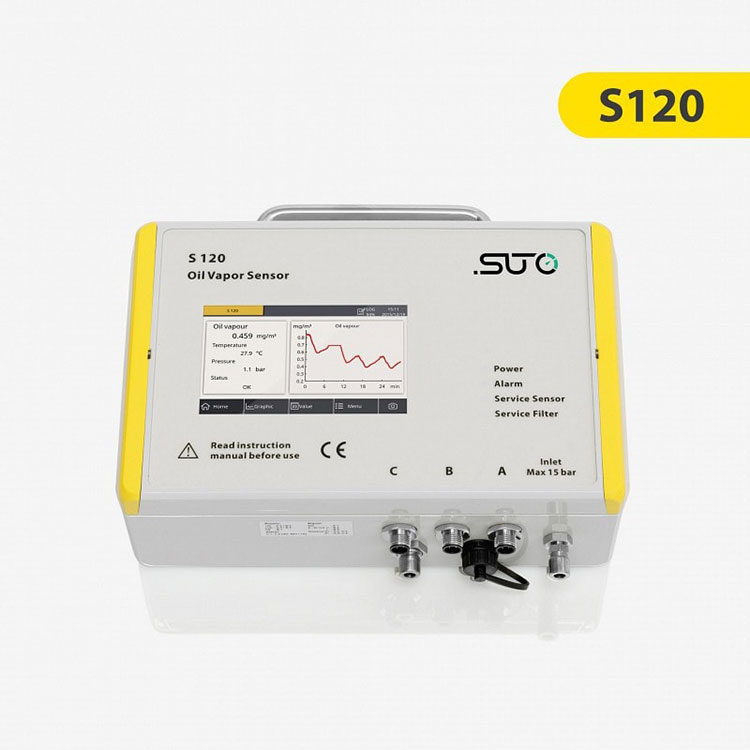

Stationary Compressed Air Purity Monitor

The SUTO S601 Stationary Compressed Air Purity Monitor offers continuous measurement and monitoring of compressed air contaminants, including Dew Point, Oil Vapor, Particle Concentration, and Pressure in real time. This comprehensive monitoring solution integrates state-of-the-art technology into one user-friendly package, providing businesses with a seamless and efficient way to ensure the purity and quality of their compressed air systems.

Model:S601

Send Inquiry

S601 Stationary Compressed Air Purity Monitor

24/7 Compressed Air Quality and Purity Monitoring

Product contamination poses a significant threat to businesses and their customers, jeopardizing both reputation and safety. Traditional approaches, such as spot checks and random testing of compressed air systems, fall short in promptly addressing contamination events and ensuring continual control over contamination levels. In today's dynamic production landscape, real-time and continuous monitoring is paramount to safeguarding product integrity. The SUTO S601 offers a proactive solution by monitoring contaminants, providing businesses with peace of mind that their products and customers are shielded from potential harm.

Compliance with the ISO 8573-1 Standard

Thanks to SUTO's pioneering sensors and technological advancements, the S601 is meticulously designed to monitor air purity parameters in strict accordance with ISO 8573-1 standards. It offers continuous monitoring of particle, dew point, and oil vapor contamination, with all data conveniently stored for future reporting. This all-in-one device streamlines the monitoring process, providing businesses with comprehensive and reliable air purity assessment capabilities, ensuring adherence to stringent quality standards and safeguarding product integrity.

Integrated Data Logger for Data Analysis

The data logging function ensures records are kept intact and stored. Real-time information can be then retrieved from the S601 by SCADA systems via Modbus outputs. The integrated color touch screen display also allows users to view all information locally.

Alarm Indication

Alarm points can be set to trigger if contaminants hit the selected limits. An optional external light or siren can be added to the alarm.

All Measurement Ranges at a glance

- Particle measurement from 0.1 < d ≤ 0.5 µm, 0.5 < d ≤ 1.0 µm, 1.0 < d ≤ 5.0 µm

- Pressure Measurement (0.3 … 1.5 MPa)

- Dew point measurement from -100 to +20°C Td

- Oil vapor measurement from 0,001 bis 5,000 mg/m³

Easy Installation and Connection

The S601 Stationary Compressed Air Purity Monitor is quick and easy to install, just connect the unit to power and the compressed air supplies with a user-friendly 6 mm quick connector. The Robust IP54 wall mountable casing provides high protection in industrial environments.