- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

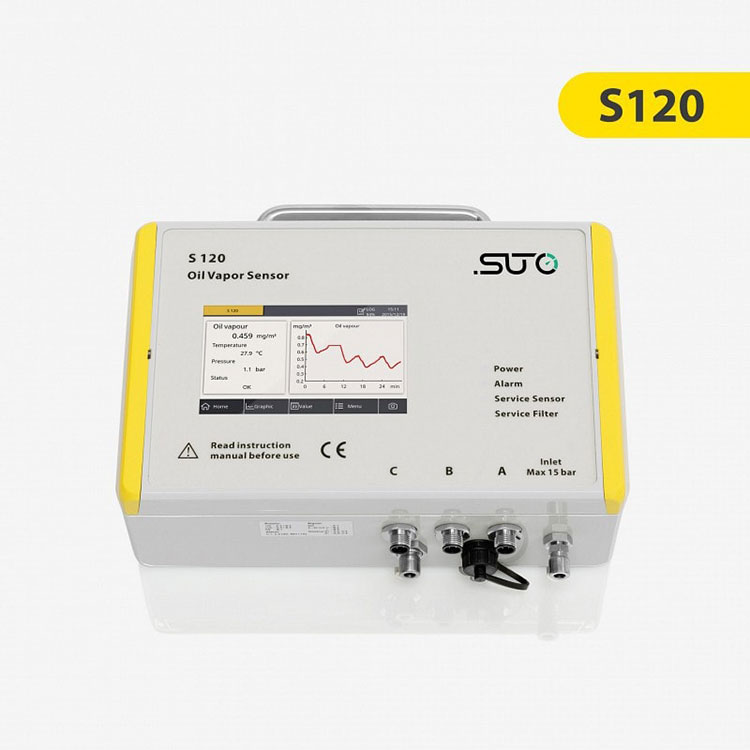

Oil Vapor Monitor for Compressed Air Purity Measurement

The S120 Oil Vapor Monitor for Compressed Air Purity Measurement is adept at assessing the purity of compressed air and gases, whether for continuous monitoring or spot checks. When employed as a portable unit alongside the S551 Portable Data Logger, it offers flexibility for on-the-go assessments, enabling users to conduct comprehensive analyses of compressed air and gas contents. This dynamic combination ensures accurate measurements, whether for routine monitoring or targeted evaluations, catering to diverse industrial needs with precision and reliability.

Model:S120

Send Inquiry

S120 Oil Vapor Monitor for Compressed Air Purity Measurement

The S120 Oil Vapor Monitor for Compressed Air Purity Measurement stands out for its straightforward installation and exceptional performance, making it the prime choice for measuring residual oil vapor contents. Equipped with a built-in PID sensor, it ensures the highest level of accuracy for reliable oil vapor monitoring.

Ensuring the Quality of Your Compressed Air

Achieving oil-free compressed air is a challenging task, yet vital in many industries and applications to prevent product contamination and safeguard human health. The S120 Oil Vapor Monitor for Compressed Air Purity Measurement facilitates affordable and dependable monitoring of oil vapor within a range of 0.001 to 5.000 mg/m³. Simply connect your compressed air system via the sampling hose and quick-connector for seamless operation.

Display Options and Versatile Output Signals

For user convenience, the optional integrated 5” touch screen display with data logger function enables easy data viewing and storage. Additionally, various output signals including 4-20 mA (isolated), Modbus/RTU (RS485), Modbus/TCP (Ethernet), and USB allow effortless connection to SUTO Data Loggers and Displays or central building management systems.

Integrated Automatic Calibration

The integrated automatic calibration feature compensates for temperature and humidity drifts in the supplied air, ensuring accurate, reliable, and stable measurement results over an extended period.

Optional Integrated Dew Point Sensor

In addition to oil vapor monitoring, maintaining compressed air quality requires monitoring dew point as a crucial parameter. To address this need, we offer an optional integrated Dew Point Sensor (-100 to +20°C Td), allowing measurement of both parameters in one compact device with an excellent price-performance ratio.

SUTO Exchange Service

Our exchange calibration service eliminates downtime and ensures seamless record-keeping of your oil vapor monitoring. For further information or assistance regarding your specific application, please don't hesitate to contact us. We are committed to finding the optimal solution tailored to your needs.