- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

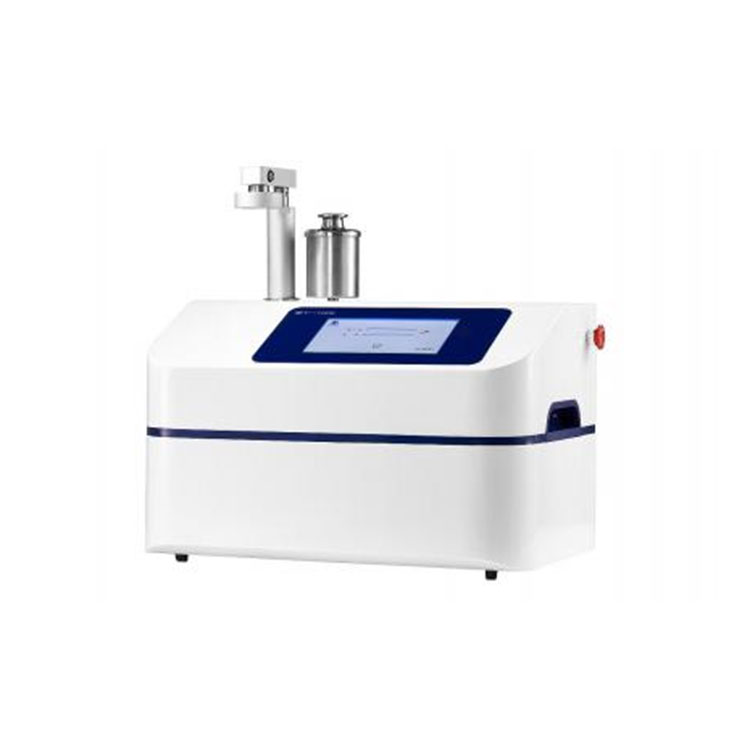

Packaging Leak Tester

The high quality packaging leak tester is a device used to detect and quantify leaks or defects in packaging materials, such as containers, pouches, or bottles. Ensuring that packaging is properly sealed is crucial for preserving the quality and integrity of the contents, especially for products like food, beverages, pharmaceuticals, and chemicals.

Send Inquiry

Packaging Leak Tester

It is suitable for sealing integrity testing of pharmaceutical packaging to prevent moisture, oxygen, and microorganisms from contaminating products. Medicines: bottled, bagged, boxed, ampoules, vials, cartridges, prefilled needles (PFS), (BFS), (FFS), etc.

Spray cans: plunger spray cans; bag-lined spray cans; "energy jacket" spray cans; flexible tube spray cans.

Features:

● Comply with USP <1207>, ASTM F2338 standards and FDA standards.

● Semi-automatic detection, suitable for small batch and multi-variety testing.

● Non-destructive non-destructive testing, high accuracy, repeatability,sensitivity.

● The instrument is used for vacuum pressure difference detection.

● The leak rate can be automatically converted into defect aperture μm.

● Database storage of test results for easy quality management.

● Touch-type man-machine interface, simple and quick operation: after setting/selecting the test program, only need to manually put in/take out the test sample.

Advantage function:

● Automatically test the flow rate and change the aperture size during the whole process.

● Automatic leak rate calibration function.

● Equipped with standard leaks (standard positive bottles, with third-party certification).

● Four-level user authority management meets FDA 21CFR PART 11 requirements.

● With audit trail function.

● Split design, the test chamber is located above the host, and various test chambers can be provided according to different product types.

● We also provide users with supporting services related to tightness testing, including positive bottle production, standard leak rate/annual leak verification, new sample mold customization, sample methodological parameter development and verification, etc.

● The test cavity is customized according to customer needs to ensure that the test cavity is fully matched with the customer's product, and rapid and sensitive testing.